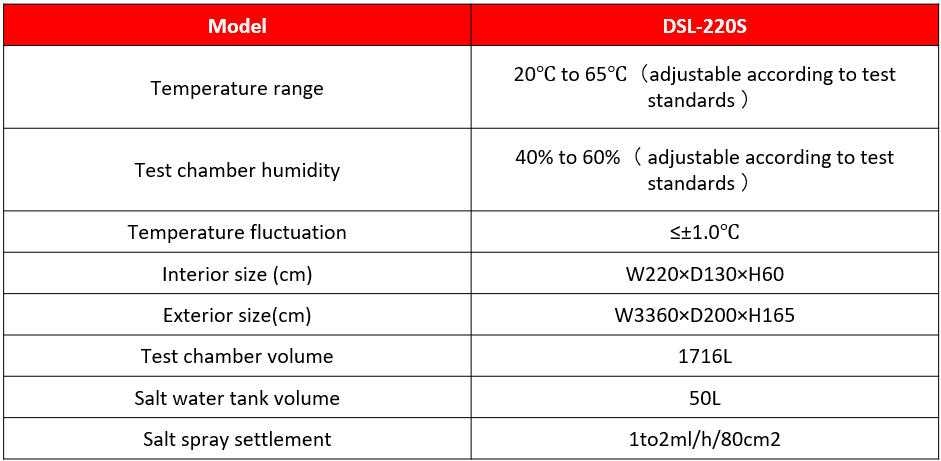

Composite Salt Spray Test Machine DSL-220S

The composite salt spray chamber is designed to simulate natural conditions for accelerated corrosion testing, combining common environmental conditions such as salt spray, hot air drying, humidity, and low temperature in any sequence for testing.

Mainly used for testing items subjected to harsh environmental conditions, such as automotive parts, aerospace equipment, building materials, coatings, and electrical machinery.

$16,905.00

Description

The machine’s inner and outer chambers are made of high-temperature, high-humidity, and high-corrosion-resistant A-grade gray PVC (8mm thick), using advanced belt-type 3D reinforcement technology, welded for strong and durable structure, suitable for various test specifications such as salt spray and copper-accelerated acetic acid salt spray (CASS).

Hidden integrated reagent replenishment bottle, easy to clean and operate.

Made of SUS304# stainless steel, with a refined tank structure design, resistant to high temperature, high humidity, high pressure, and high corrosion. After years of experience, it has successfully solved the technical problem of water shortage in the pressure tank of ordinary salt spray machines in the market. The unique internal design of the pressure tank ensures that water shortage is no longer a concern during testing, leading the industry.

Working Principle

The salt spray system consists of a solvent tank, variable-speed magnetic pump, pneumatic system, water tank, spray tower, nozzle, and other compo- nents.

The pump transfers water from the storage tank to the test chamber, while the heating tube provides the required humidity and temperature inside the chamber. The salt solution is atomized by compressed air through the spray.

The spray tower is detachable for easy cleaning. During salt spray operation, when the low water level switch detects a low water level, the water tank heater turns off, and the spray stops. The water level device automatically fills water through the water inlet solenoid valve until the high water level switch detects a high water level. When the water inlet solenoid valve stops, the heating tube starts working.

When the program requirements are met, the spray will automatically start.